The Significance of Digitizing in Pattern Making

Garment production consists of several phases which follow each other in a straightforward fashion. Manufacturers utilize various machinery and software technologies in order to reduce the time spent within and between each of these phases and increase productivity. These steps fall into two categories which are design and manufacturing. The design process consists of digitizing, pattern making/alteration, grading and finally marker making. Once the marker is ready the production phase can start which consists of cutting, sewing, printing(if needed), packing etc.

The Role Of CAD/CAM Technology

Productivity in apparel manufacturing highly depends on the machinery technology and labour quality whereas the significance of CAD/CAM software in design process is paramount. Today in the design room of a modern garment maker or fashion designer each step of the design process is computerized by using CAD software. Pattern design, grading and marker making are done by specialized programs which speeds up the design process significantly. These programs are sophisticated and have numerous functions which require intensive training and user expertise in order to make use of them efficiently.

Pattern Digitizing: An Overlooked Step

Pattern digitizing has not been receiving the attention it should get despite being a significant part of pattern design process in terms of time spent. This is partly due to lack of user awareness of alternative technologies and the other reason is hesitation of users when it comes to using a new technology. Digitizing process can take a large amount of time when it is done by conventional table and mouse digitizers manually. In this way of digitizing each pattern is traversed by a digitizer mouse one click at a time which slows down the process. Also patterns have to be fixed on the table using adhesive tapes and these tapes should be removed once digitizing is completed. This damages patterns as well.

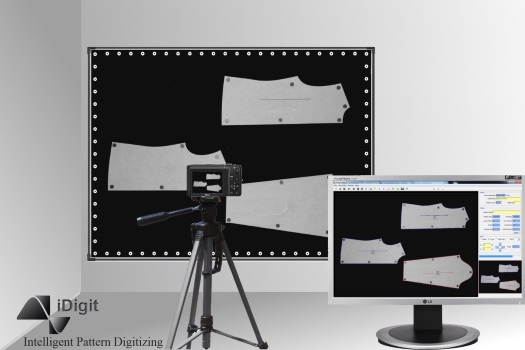

A Brand New Way Of Pattern Digitizing: iDigit

It is possible to reduce the time spent with pattern digitizing from several minutes to just a few seconds by using iDigit. Considering the percentage of time spent with manual pattern digitizing in the whole design process and the huge difference of speed with manual digitizing vs photo digitizing, it is clear that iDigit improves productivity by cutting down the time and effort spent with digitizing step. Designers can then proceed with the process and spare their time and energy for style design, pattern grading and marker making which leads to a shorter production time. Learn more